Harvest report 2023

The 2023 grain and maize harvest was characterized by extremes. Severe drought and then persistent rain was a major problem for many.

For the first time, there was a satisfaction guarantee for parts in the catchment area of Zangs Harvestbooster. A single part from a single customer was returned. Overall, all customers were able to recognize the benefits. There are many more recommendations.

The parts will remain unchanged in the 2024 season, for which we would like to express our special thanks.

Our parts were also able to prove their effectiveness in an extensive comparative test. With the same throughput capacity, significantly reduced losses and, in this case, almost 4 % less fuel consumption. And this under very simple conditions in standing wheat where no difference in crop flow was visually discernible.

No additional broken grains or impurities were detected in the grain. Additional output was not utilized, but would have been possible.

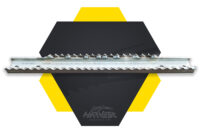

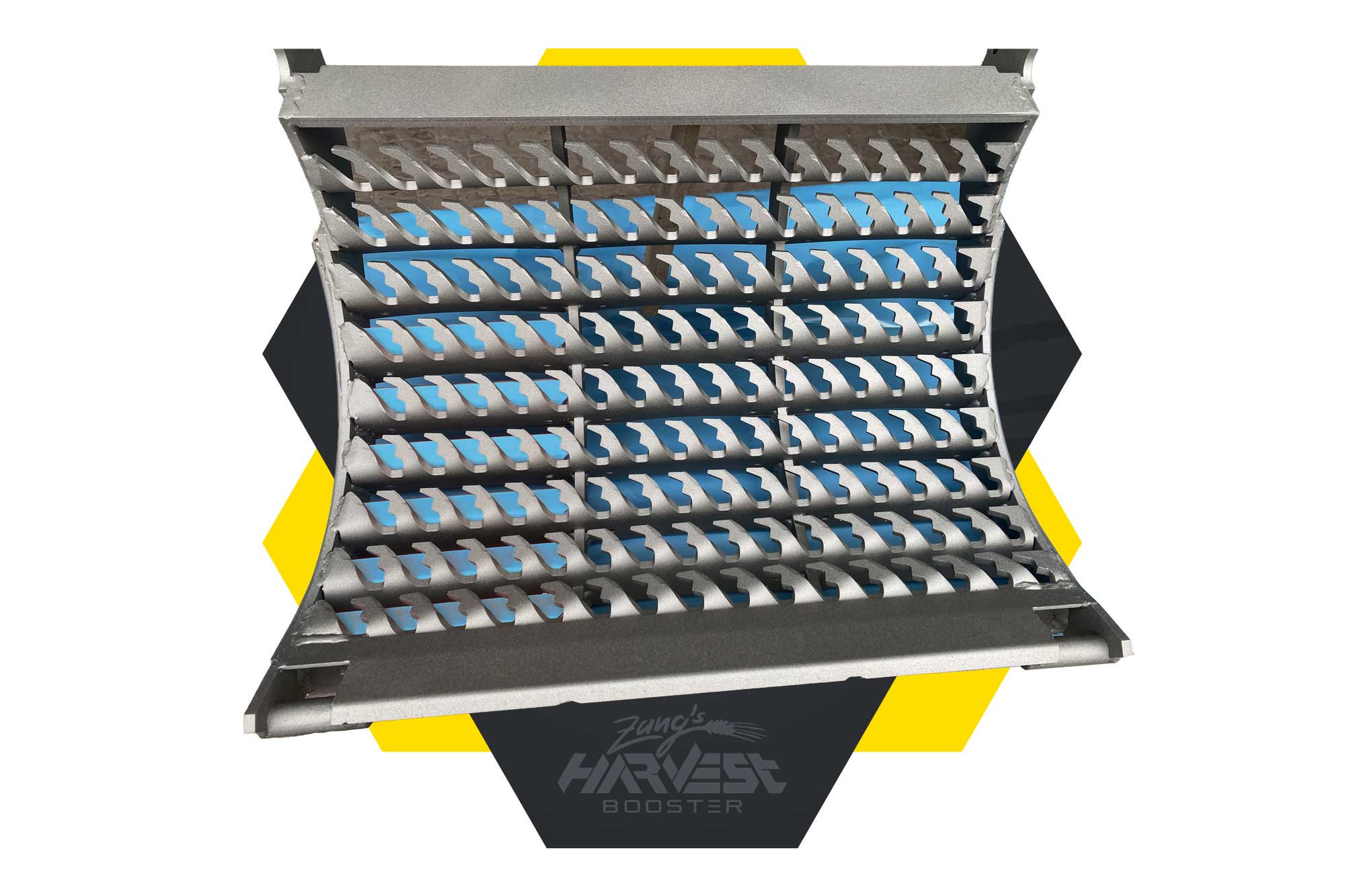

The new threshing concave

With the new concave, some record throughputs were achieved in all crops. In a New Holland CR 9.90 demonstrator, which was equipped with our main concave in In combination with the Mc Don cutting unit with 12 meters, a grain throughput of over 100 tons per hour was achieved in many cases.

Markus Trost was the driver of the TAM machine in Thuringia for the entire season and reports:

“Winter barley, wheat, durum, oilseed rape, peas, sunflowers and spring barley, everything went

perfectly”, “With Lexion 8700 one day together on the same field 2 ha more with less fuel in the same time”, “Clear advantages when it gets damp and no problem with short straw” was his summary.

In the John Deere S Series, Andreas Guthörle was also on the road with the basket in soybeans and maize. “Very high performance in all crops and smooth machine operation, especially in rapeseed” is what he noticed. In soybeans, the seed quality was very special, with

0.18 % broken grains determined in the seed company’s laboratory. Top quality was also harvested in maize.

We also achieved top results in Austria:

Mathias Bangerl from Raab in Upper Austria grows over 60 different crops. He has installed the parts in his Tucano and speaks of a 15% increase in performance.

The advantages were present in all crops, no part had to be taken away again, even with oil flax, for example, which can be particularly difficult.

For him, it was particularly important that the straw distribution of the chopper has become much better. Others have also reported this and it is due to the uniformity of the feed.

www.blumensaat.at

Josef Neubauer, also in Upper Austria, has achieved a very high annual output with his brand new

New Holland CR 8.80 and Harvestbooster full equipment. Also including a lot of soy and maize.

He says that with this “small CR” 8.80 with Harvestbooster he achieves at least the same

performance as with the large New Holland CR 9080 with standard equipment and 9.15 meter

cutterbar width.

Alexander Achleitner and Stefan Hofer are also based in Upper Austria near Wels and have had

the same experience in a CASE 6150 and 8250 respectively.

Very smooth machine operation and high separation efficiency in all crops.

Our sales partner for Case machines in Austria is the company Söllinger in 4625 Offenhausen,

contact person Stefan Hofer.

www.soellinger-lt.at

And in Switzerland:

Our sales partner, customer and supporter in Switzerland is Daniel Kressibucher. He lives in 8506

Lanzenneunforn and has used, helped develop and supported the parts from the very beginning.

www.agrar-verschleisstechnik.ch

Many thanks to all customers and the many feedbacks. This is just a small excerpt.

The parts have now been tried and tested several hundred times.

Günter