Do you know this?

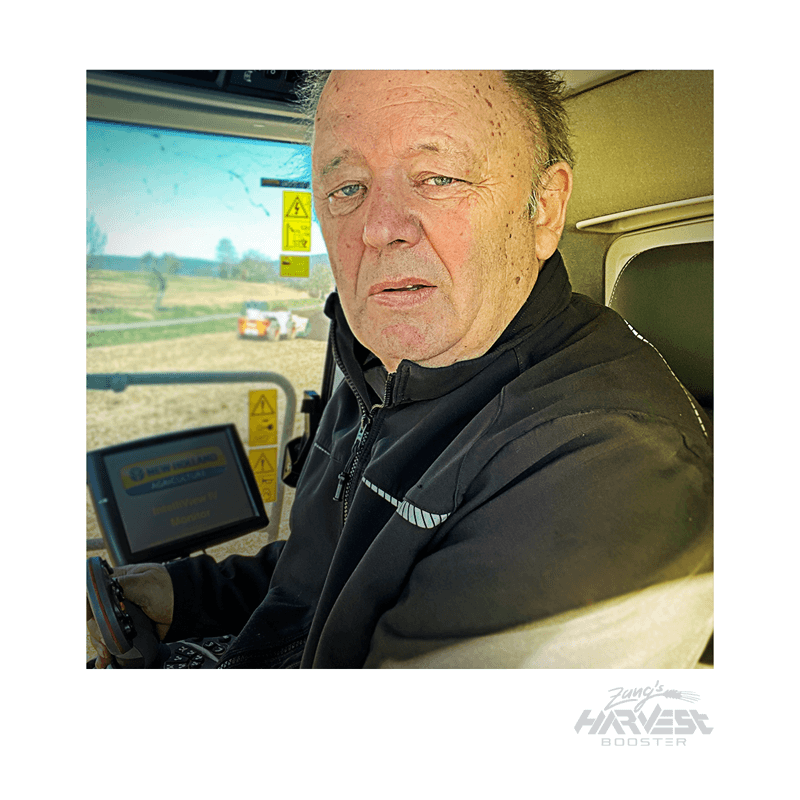

The harvest is imminent, but the weather conditions only offer a short window of time for an optimal grain, or even rapeseed, beans, etc. harvest. Then performance is required. But the grain does not flow as it should. There is a problem separating the grain from the straw and the machine struggles with too little power?

You’ve probably tried a lot of things? Machine settings turned up and down with more or less success. The promised, expected and often necessary harvest performance is not achieved.

We have tools for you that can help a lot, we even give a 100% satisfaction guarantee!

There are now hundreds of experiences from users in different countries who help us to make reliable recommendations so that your machine runs more smoothly and performs better at the same time. Simple components in the feed area that can be adapted to any machine and, above all, achieve very high uniformity in the crop flow. Or threshing and separator baskets that are no longer changed, from winter barley to grain maize, and also achieve better separation efficiency with less power required and better straw quality. This is real sustainability, more performance with less consumption! In a top-class comparison test, our statements about the additional performance were exceeded, and that with a loss rate halved!

If this sounds interesting to you, we can talk together about the possibilities on your machine and put together a suitable package.

A first overview of our tools and starting points can be found here on our website and also especially the You Tube channel – Zangs Harvestbooster – with many authentic reports from customers and harvest applications.

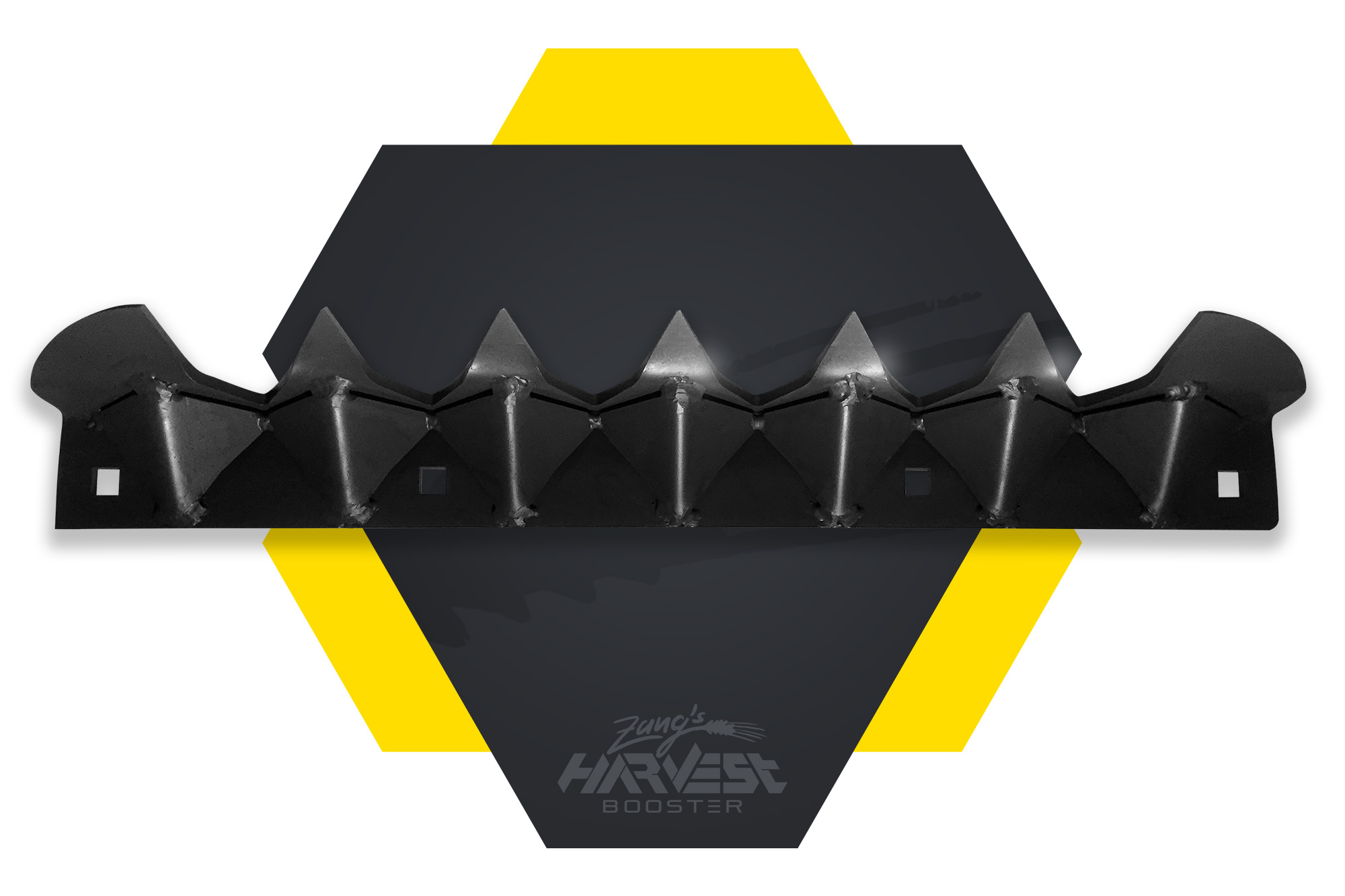

The retrofit kit for combine harvesters

to increase efficiency.

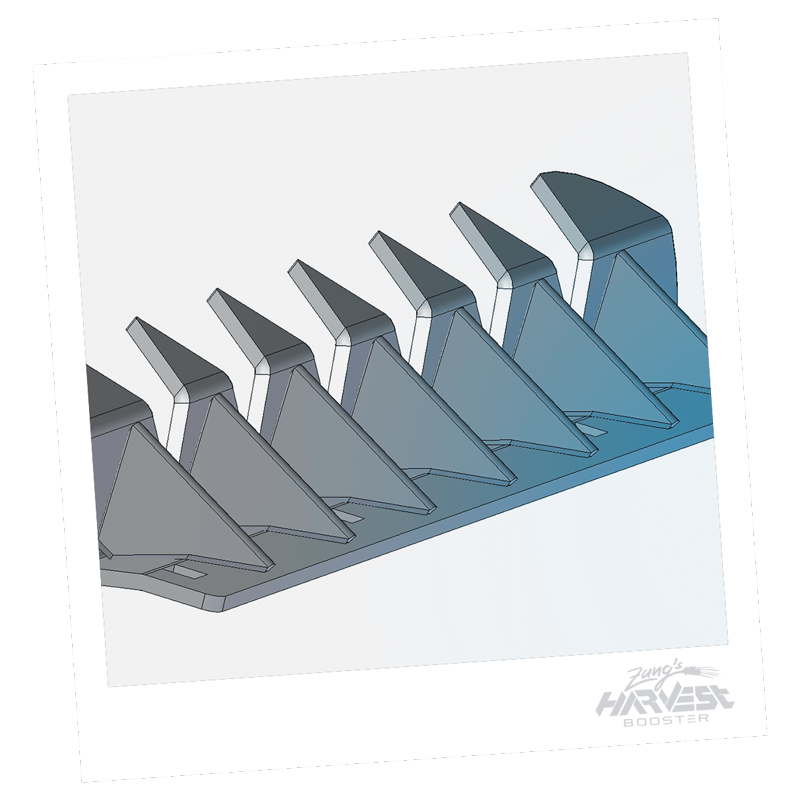

Zang’s Harvestbooster consists of several utility model-protected and patent-pending components

that we have installed, tested and further developed on our combine harvesters.

We build the parts ourselves and put them up for sale.

Product areas

Parts in the catchment area:

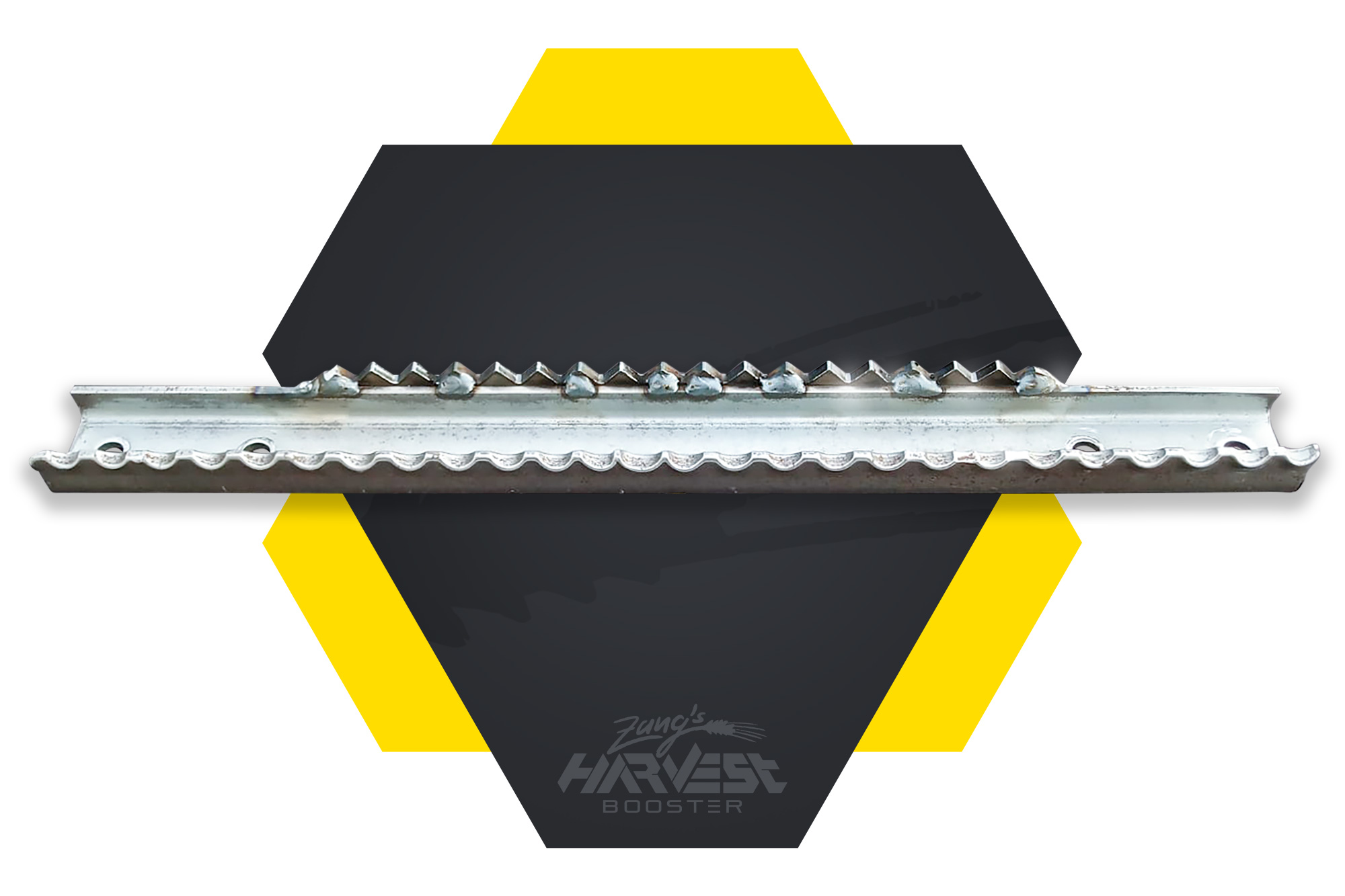

> Charging bar

> Grip strip

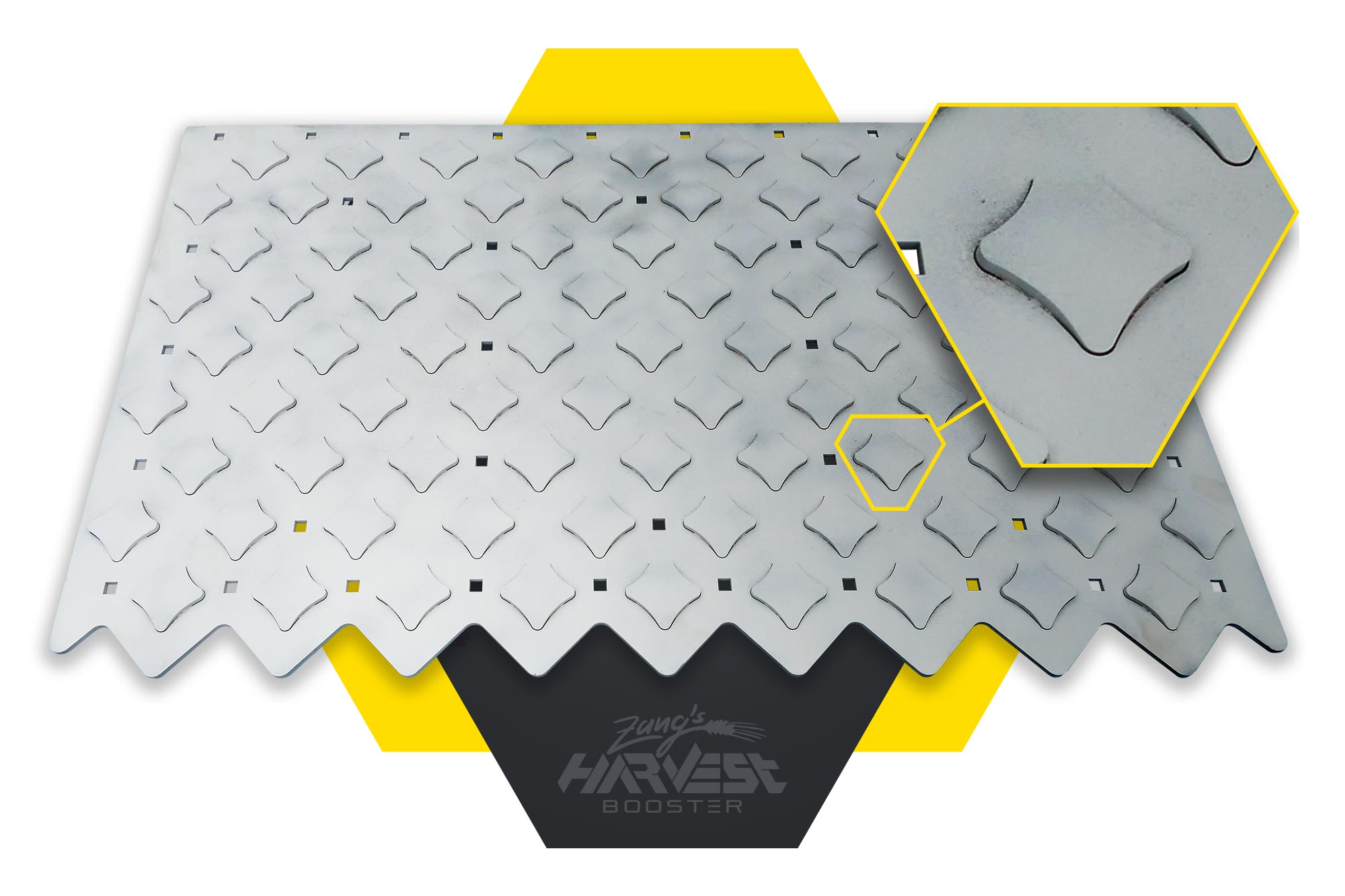

> Ear loosening plate

> Skids

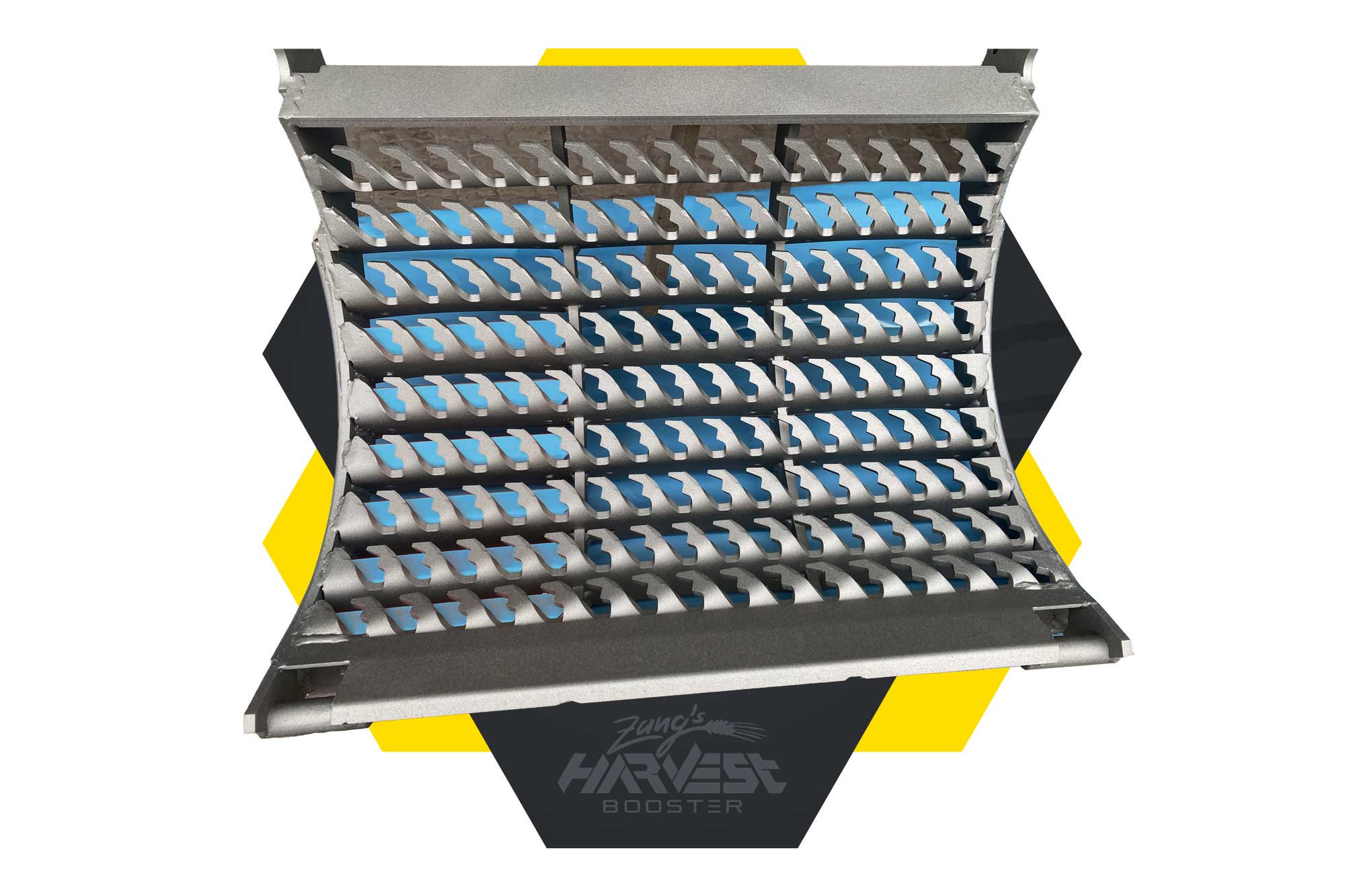

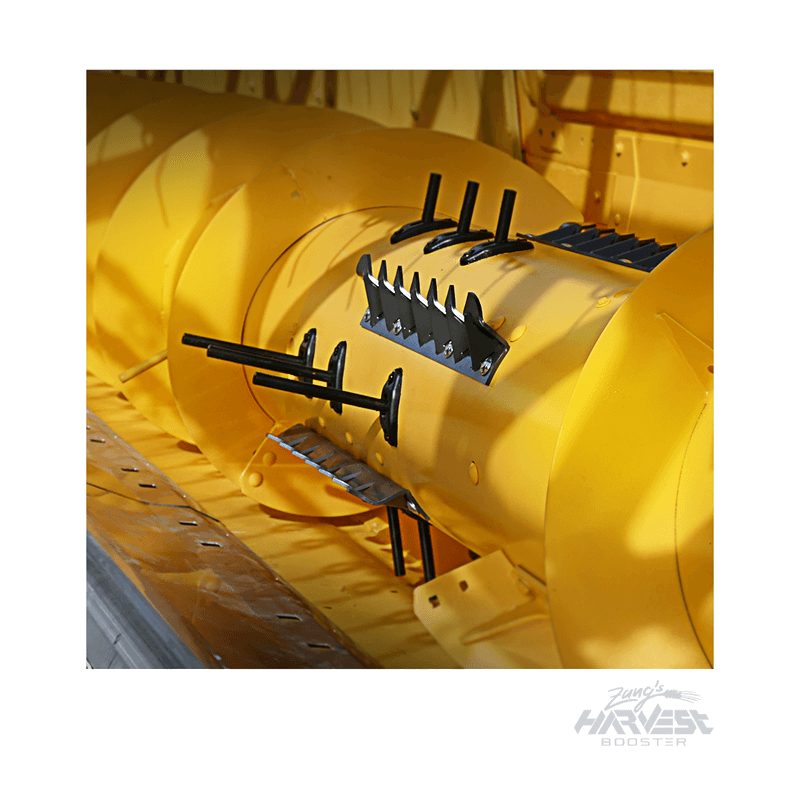

Parts in the rotor area:

With 100% satisfaction guarantee

If, contrary to all previous experience, you are not satisfied with the result after correct installation in accordance with the instructions and documentation with pictures of the complete Harvestbooster kit (slide-in bars, grip bars, ear release plate and skids), you get your money back. 100% of the purchase price excluding freight.

The condition is that the parts are returned by August 31 of the year of purchase.

The advantages

are obvious!

Achieve more in a relaxed manner thanks to an optimized flow rate with lower engine load.

A higher proportion of intact straw ensures a better baling pattern.

Faster and more relaxed operation – the dream of every combine harvester driver.

Environmentally friendly and sustainable thanks to more efficient work and lower fuel consumption.

Exclusive parts

… only available from us!

Curious to see what happens next?

You can find out what happens next

here about our annual duck reports or follow our

social channels:

- The parts In the catchment area for all combine harvester makes.

- The universal concave for various rotor combine harvesters from New Holland, Case, John Deere and Fendt.

- The powerful and blockage-free separator concave for rotor threshers.

- Other parts, such as tangential concaves and front concaves for Claas combine harvesters, are

currently in the successful test phase.

The Harvestbooster components can be fitted to suit the combine harvester and, when positioned correctly, result in a more even crop flow and optimized draft in the intake area of the combine harvester during grain harvesting. Under all harvesting conditions, as well as with stored and moist grain, the smooth, even running results in an increase in performance. The optimized feed to the threshing elements reduces fuel consumption, resulting in noticeably fewer load peaks and no more load interruptions. This ensures top performance, even on slopes. This is our experience, which we are happy to share with you.

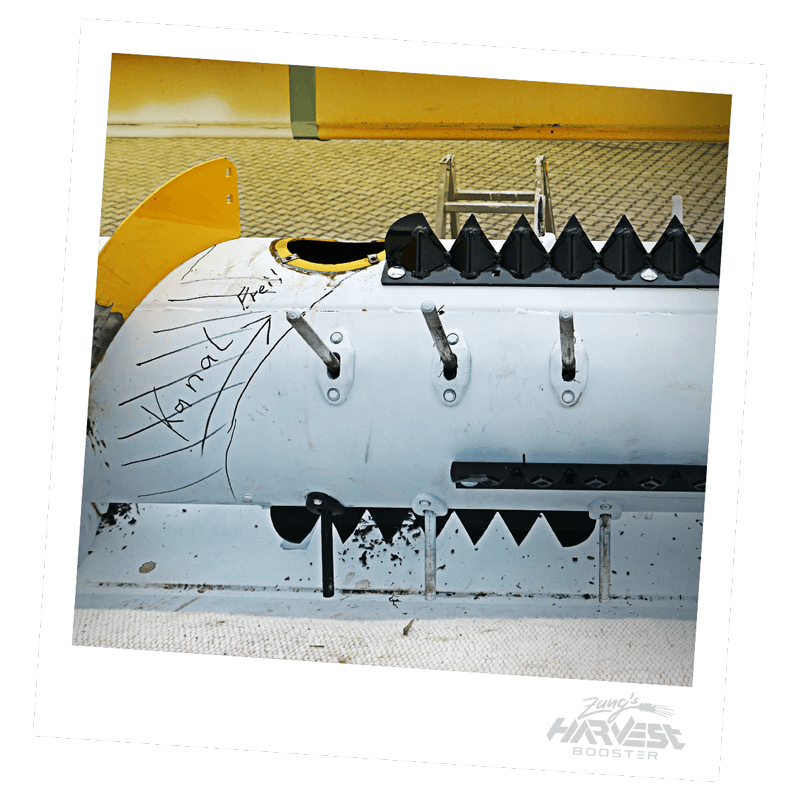

An essential element for reliable intake and greatly improved transfer of the crop to the inclined conveyor.

The gripper bar is one of the most important parts of the Harvestbooster set, enabling the crop to be removed from the cutterbar and securely gripped so that it can be pulled over the ear lifting plate without delay or slippage in the inclined conveyor.

Our ear opening plate ensures optimized removal of the grains from the ear. Optimally positioned, it ensures that more grains are released.

The advantages of our new concave are its remarkably smooth and quiet running, even when the crop is still green and moist.

Additional components

In order to meet the specific requirements of individual combine harvester brands, we have developed additional components that can be fitted and adapted. This allows our Harvestbooster to work efficiently on many different combine harvesters.

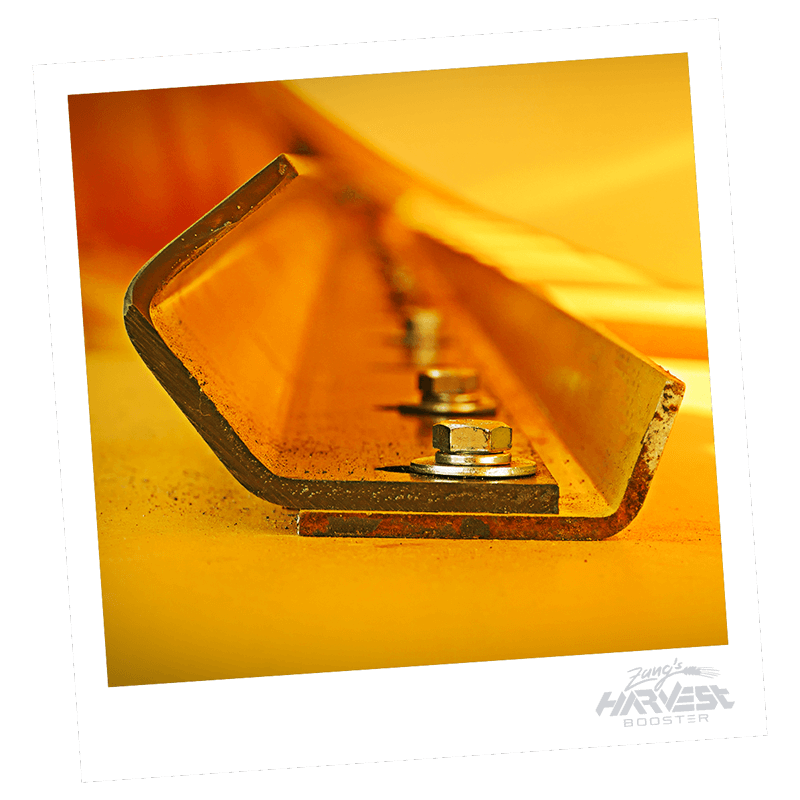

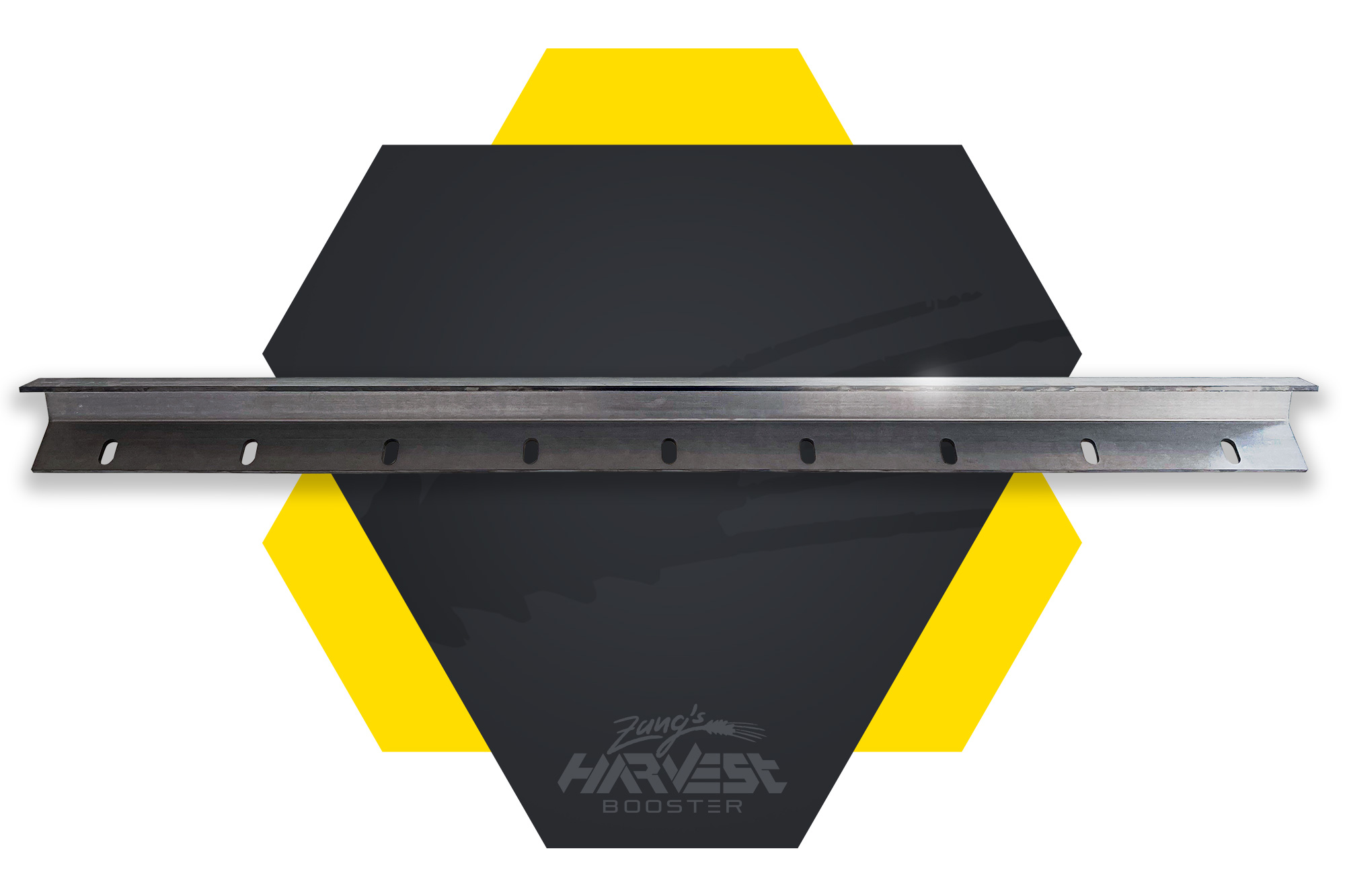

Scraper strip

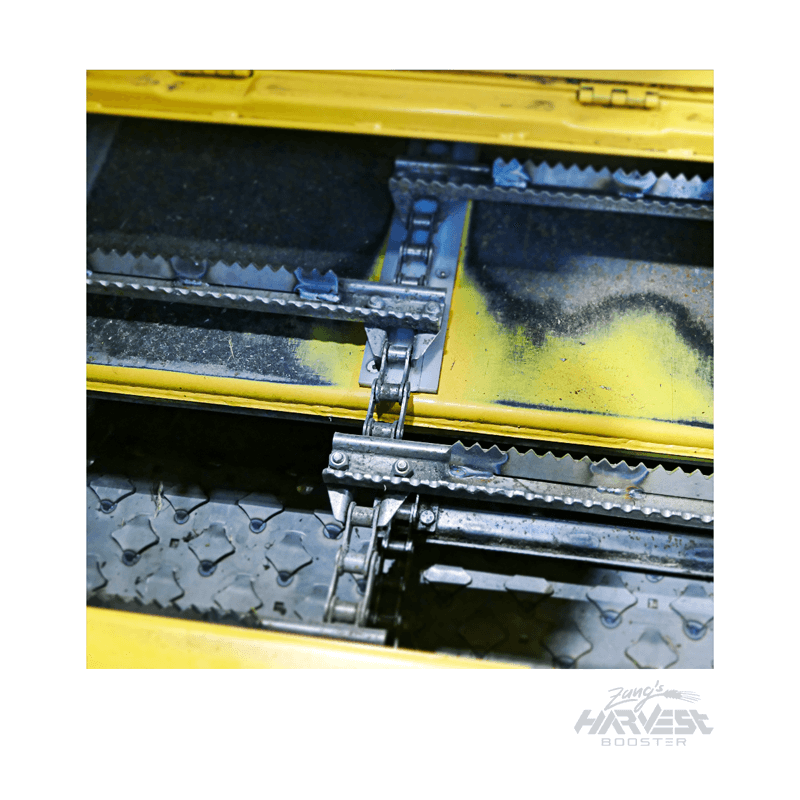

Our scraper bar has been specially designed for Case and New Holland combine harvesters. This solves 100% of the problem when the original bar cannot be set narrow enough for large working widths and material is carried around in a circle.

The scraper strip consists of a double-edged strip that forms a narrow channel and thus represents a kind of double lip.

The strip is an addition to the original strip. After loosening the relevant screws, it is attached to these and screwed together at the existing points.

The parts are supplied in 120 cm lengths. As a rule, 2 such scraper bars are recommended on the right and left side of the cutting unit. These do not have to reach all the way to the outside, as there is no problem on the outside.

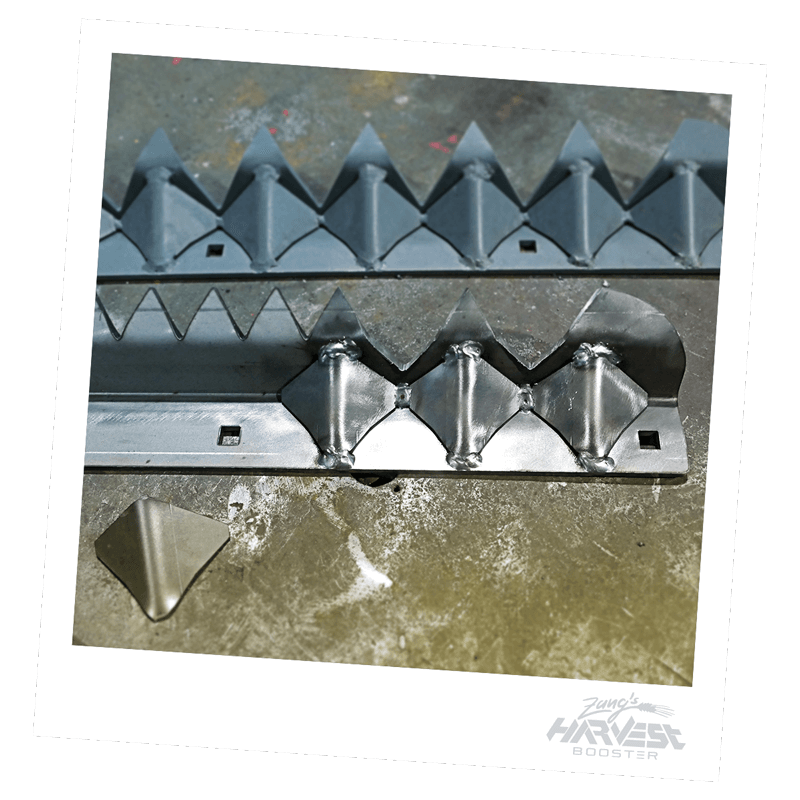

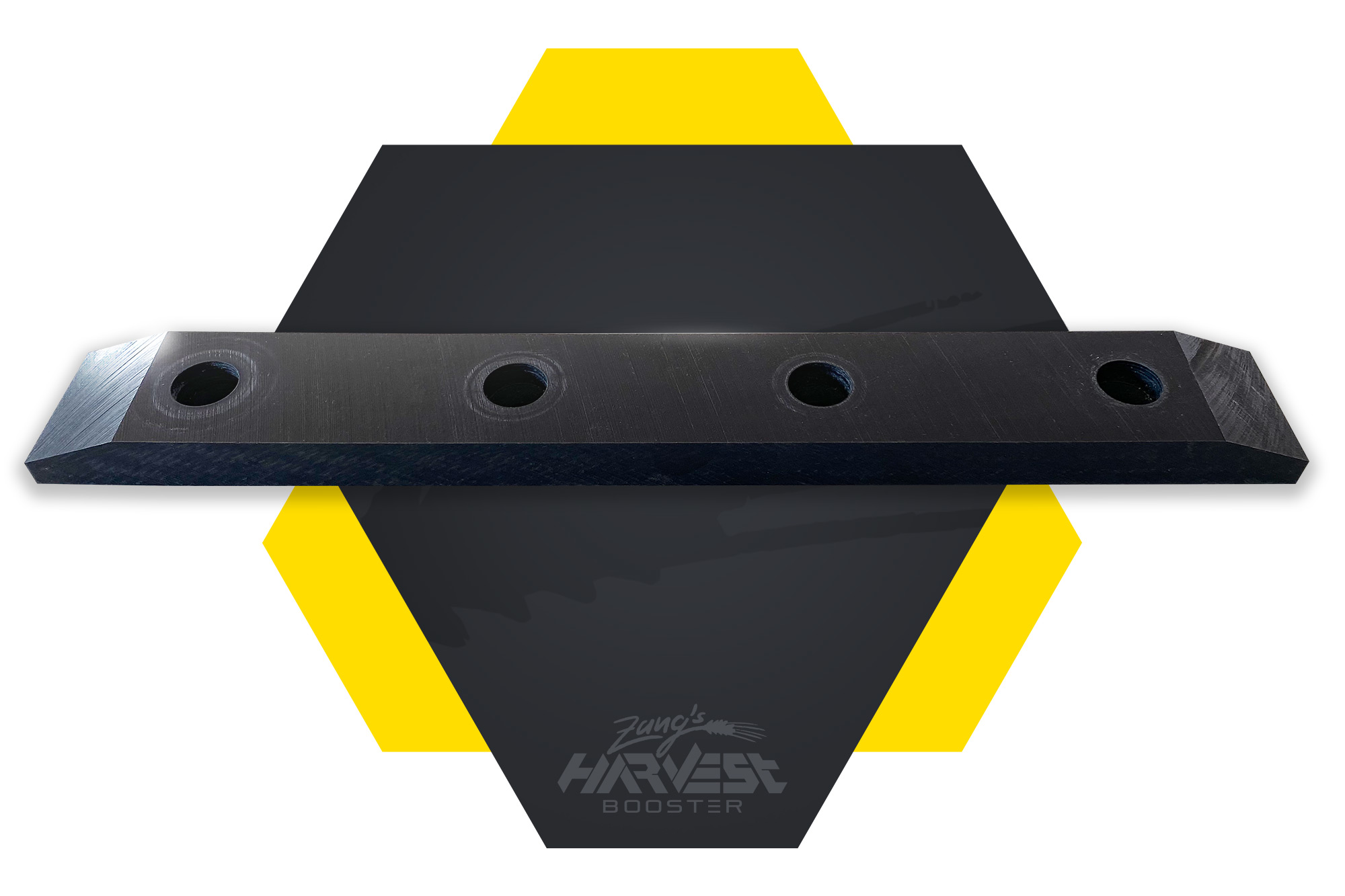

Skids

Sliding skids prevent sliding contact between the feed bars of the conveyor chain and the ear lifting plate. They are also required on some machines that have a long inclined conveyor and the chain tension is not sufficient to carry the chain freely. Our skids are made of hard and proven special plastic with 4 holes for countersunk screws, dimensions 20 x 50 x 420 mm.

The runner is integrated into the ear release plate. The plate is cut out 50 mm wide in the last third at the corresponding point. The runner is placed in this cut-out and attached to the floor.

Send request

Give us a call or simply send us an inquiry by e-mail so that we can respond to your specific questions and you can find out more about prices and processing.

+49 (0) 170-8909243

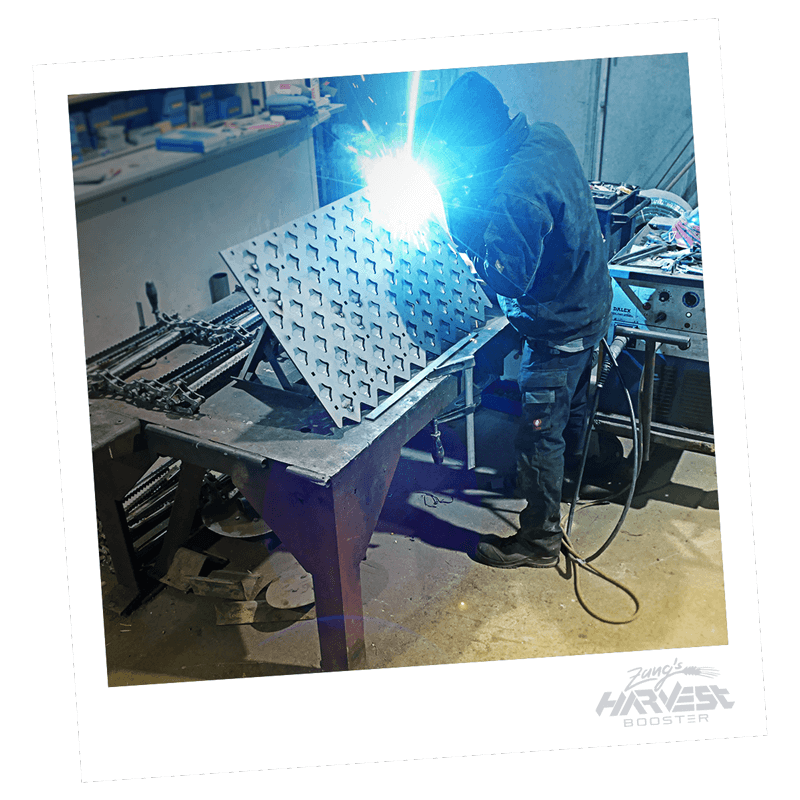

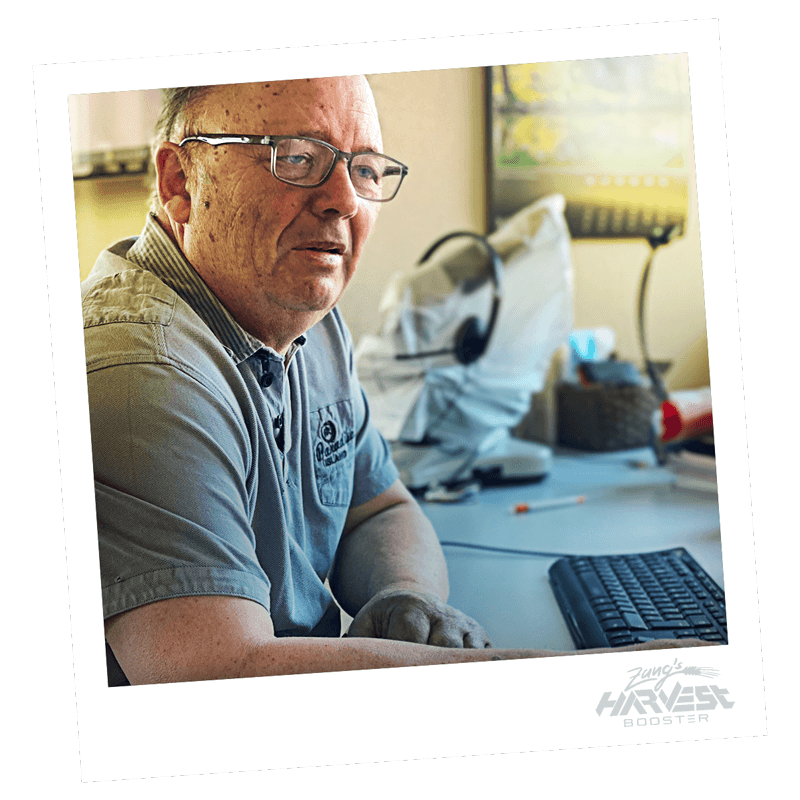

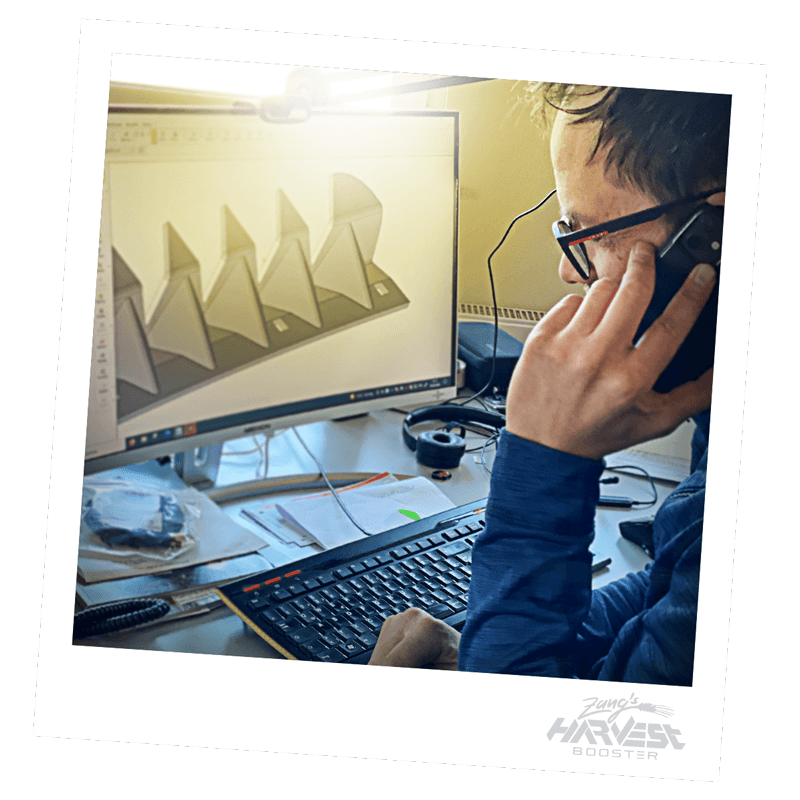

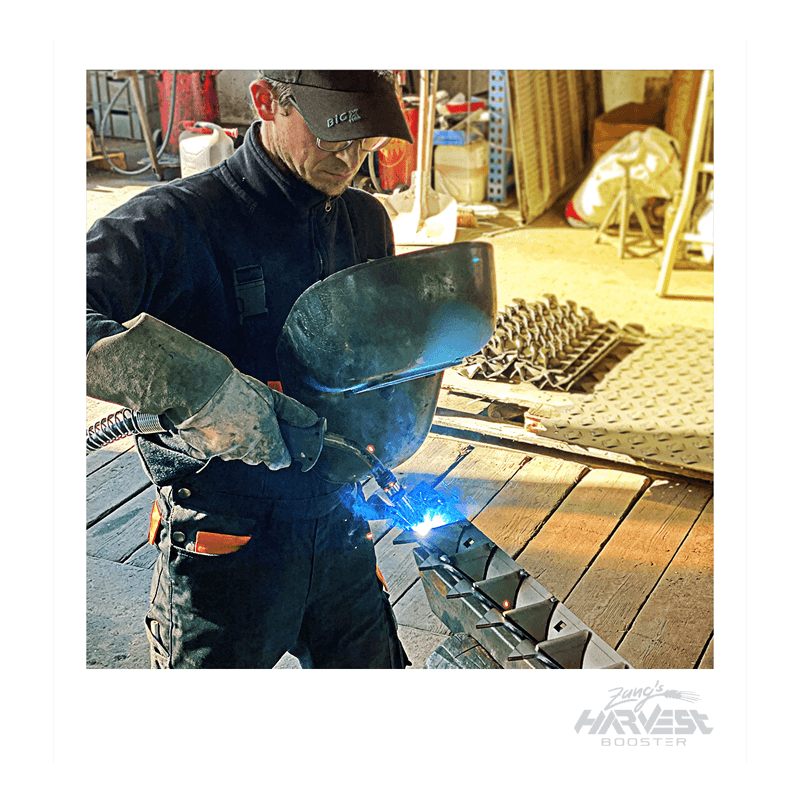

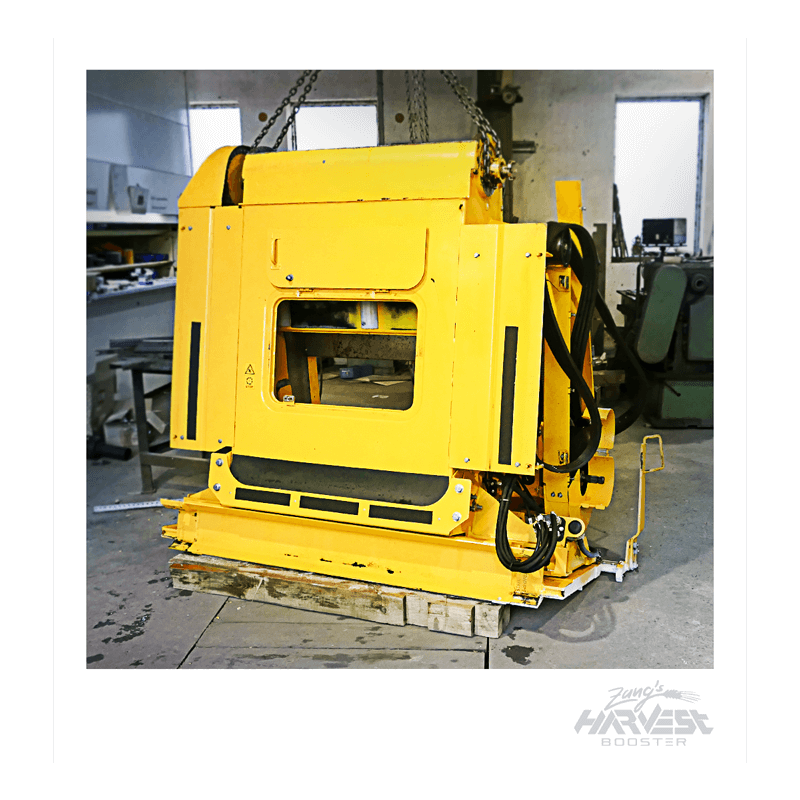

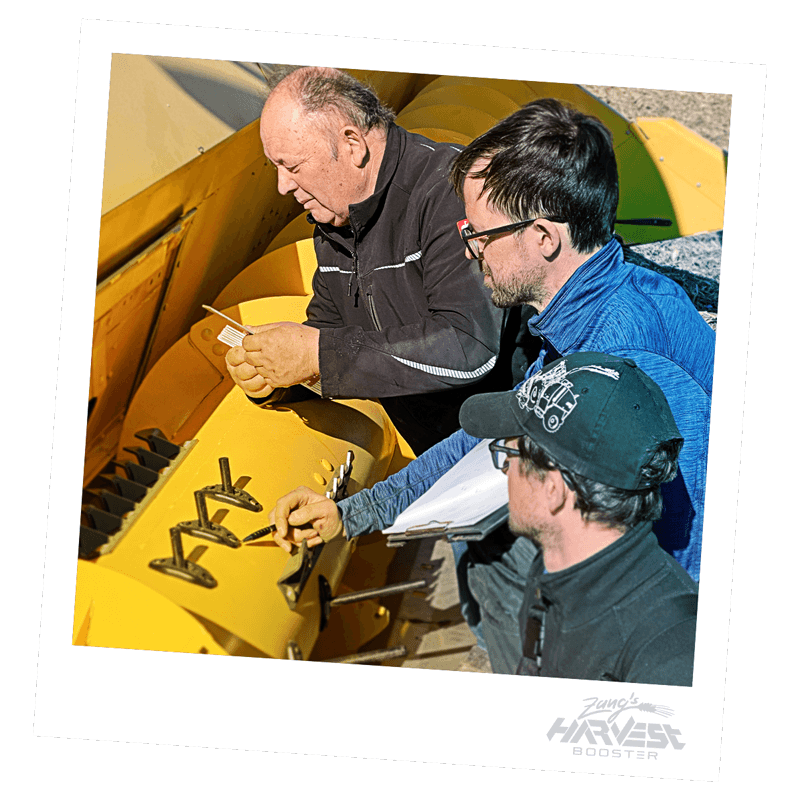

View into the workshop

The parts of the Harvestbooster are in-house developments. What began as an idea has developed into a technically sophisticated concept in recent years, consisting of several parts that can be easily retrofitted individually to many combine harvesters. We design and develop our parts at our desk, but also manufacture them directly in our workshop. This gives us control over the materials and workmanship. On our

We also sell these parts to many other farmers, contractors and threshing enthusiasts who share the same passion as we do – “relaxed performance”.

… from the idea to the field!