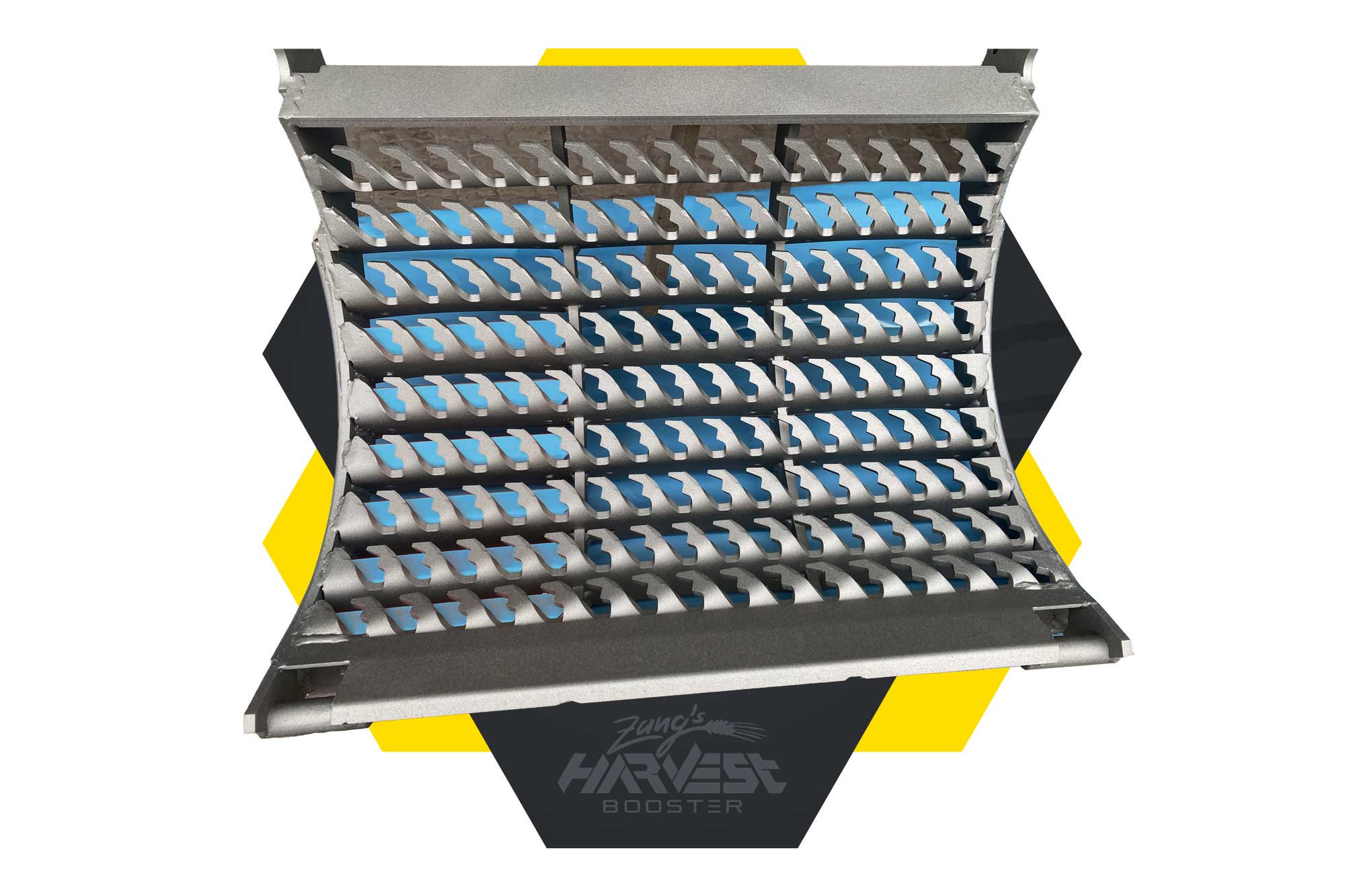

Harvestbooster threshing concave

We present the third generation of our extremely powerful threshing concave.

It offers many advantages.

Our new concave is a true universal concave. It runs remarkably smoothly and quietly, even if the crop is still green and moist.

There is very good experience in cereals, rapeseed, sunflowers, soybeans and corn.

In an elaborate comparison, we were able to determine an average motor power reserve of 4% using our basket alone.

With a combination of basket and feed parts, we achieve a good 14 % power reserve with a significantly reduced loss rate.

The Harvestbooster concave is currently available for 5 different rotor combine harvesters::

– New Holland CR 8.80 rotors

– New Holland CR 9.80 rotors

– Case Serien 150

– Case Serien 250

– John Deere S-Series

Fendt Ideal 7 rotor machine, as well as Fendt and MF Tangential machines will follow for the upcoming 2024 harvest.

We were encouraged by the use of the tangential basket in a New Holland CX machine, where this design has proven itself and performed very well.

The experience of several customers from Germany, Austria and Switzerland confirms the unique advantages of our special design.

We are seeking an international patent for this basket, which, after preliminary examination, is no longer an obstacle.

The separator concave is of great importance after the concave.

The finger basket developed by us impresses with its complete freedom from blockages and very high Residual grain separation.

The difference to the standard is clear and is confirmed by all users. Highly recommended, especially in moist conditions in green soy or maize. Ideal addition to the main concave.

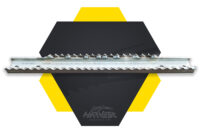

Threshing jaws

The threshing shoes are crucial tools in the threshing process and are subject to corresponding wear. They should be replaced when there is noticeable wear in order to maintain performance and threshing quality.

The threshing jaws we offer for retrofitting are characterized by their optimized shape and better results.

Many NH CR customers with S3 rotors already know this. These are the older machines without the twin pitch rotor.

We can offer these effective parts at an attractive price.

Wear edge to the S3 rotor

A small part with great significance. From feedback and our own experience, we have noticed major differences in the transfer of threshing material to the rotor.

This applies in particular to the S3 rotor and we can also offer solutions for this. Just ask us about it.

Send request

Give us a call or simply send us an inquiry by e-mail so that we can respond to your specific

questions and you can find out more about prices and processing.

+49 (0) 170-8909243