Customer testimonials

Andreas Guthörle

“Hi Günther, I just finished with soybeans. Was almost 200ha this year, has a lot of requests with seed multiplication due to the top threshing quality with your basket. Greetings Andreas Guthörle”

Rolf Rosewich

“Hello, Team Zang, I am absolutely delighted. Threshing goes smoothly despite the green straw and overgrowth. The chopper is unrecognizable. Chop quality and distribution are top. When harvesting grain millet, I was able to achieve a throughput of up to 40 tons. I was also able to harvest maize and sunflowers with a larger basket gap. One customer asked me what I had done with the machine, and he wasn’t complaining at all.”

Toni Reincke

Toni Reincke Stäbelow in Mecklenburg-Vorpommern Crop farm. Combine harvester Case Axial Flow 6140 with X-Flow cleaning Grain cutterbar vario 3050 7.62 m working width Schumacher Easy Cut II.

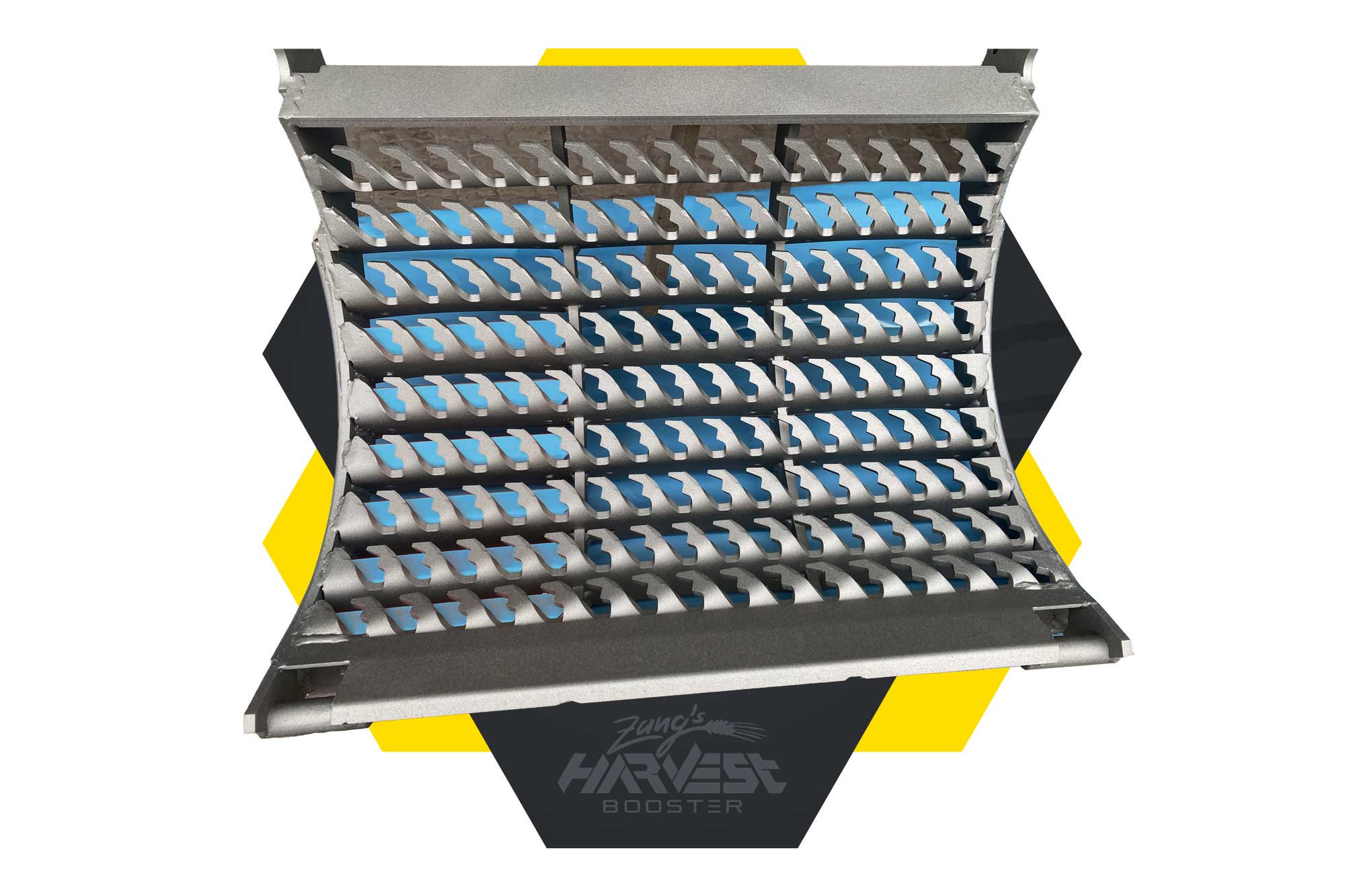

The economic miracle 2021 worked great Engine utilization with previous threshing was up to 20% lower I threshed rye organic oats and wheat. Threshing concaves could be opened wider and thus the throughput was also higher with 0.5 % losses.

Losses are checked more often with Andrea Feiffer’s test bowl dropping system as here on the Baltic Sea it does get wet early.

I have also been threshing grain maize here for four years and have been using my own Case IH 4408 F 75 picker for two years.

Here I can say that the disintegrating plate also works well there, my observation is that here in the feed chute a large proportion of the sprouts are already removed from the piston as well as a few grains here and there, depending on the variety.

I can only recommend the system to anyone with a clear conscience and also to the Installation recommendations must be observed.

Toni Reincke

Michael Bundschuh

By installing the “Harvestbooster conversion kit” in our Lexion 760+V900, we were able to improve the threshing result and the even throughput. In the case of wet straw, as is the case when harvesting green spelt, we avoid “taking it out” of the feed chute and wrapping it around the auger.

Gerald Wallner

On my NH CSX 7050 with 6.10 Varifeed cutterbar with Schuhmacher Easy Cut II, when driving downhill (more than 12°), the crop in the cutterbar often did not enter the feed chute optimally, which led to drum blockages.

I became aware of Günther’s “economic miracle” during a webinar.

After the barley harvest, I bought the complete set of the “Wirtschaftswunder 2021” and used it to install the spike breaker plate and the “Zwangsbeglückungsleiste” – exactly as Günther’s Assembly instructions. During the wheat harvest, I had a completely different combine harvester that simply devoured the wheat – with 13% more power from the machine and 11% less fuel consumption.

The ear opening plate also did a great job with the soybean harvest. Despite tough pods, I had no breakage and an optimum result without losses.

Gerald Wallner

Rohr im Kremstal/Upper Austria

Send request

Give us a call or simply send us an inquiry by e-mail so that we can respond to your specific

questions and you can find out more about prices and processing.

+49 (0) 170-8909243